Powerful, versatile, and scalable solutions for today's and future applications in high-tech industries, delivering exceptional results across the broadest range of materials—from common and advanced to those once considered difficult or incompatible.

Engineered for Precision and High Performance

Intelligently designed to deliver outstanding performance, precision, and consistent results—even for the most demanding requirements and complex geometries. Next-generation solutions feature a high-precision laser beam delivery mechanism with micron-level addressable resolution and repeatability, ensuring accurate beam positioning across the entire processing field. Sophisticated laser processing algorithms and user-driven software controls allow for fine, incremental adjustments across a range of parameters, further enhancing control and output quality.

Unmatched Material Processing Flexibility

ULS laser systems are turnkey solutions built on a modular architecture, allowing users to configure them to meet the specific needs of a single application or multiple material applications. Designed for adaptability, they support evolving processing demands across diverse environments and use cases, including R&D, product design, and production.

A single system can support multiple laser sources with varying wavelengths and power levels simultaneously. It can also be configured with processing optimization modules.

Key Features and Capabilities

- Support for multiple laser wavelengths commonly used in materials processing: 10.6 μm (CO₂), 9.3 μm (CO₂), and 1.06 μm (fiber)

- A wide range of air-cooled laser sources for each wavelength, with peak powers ranging from 10 to 300 watts

- Rapid Reconfiguration™ Technology - Allows users to change laser wavelength and power at any time—without tooling—to process different materials or applications

- MultiWave Hybrid™ Technology - Combines multiple wavelengths for effective processing of complex materials such as composites

Effective and Efficient Laser Energy Delivery for High-Quality Output

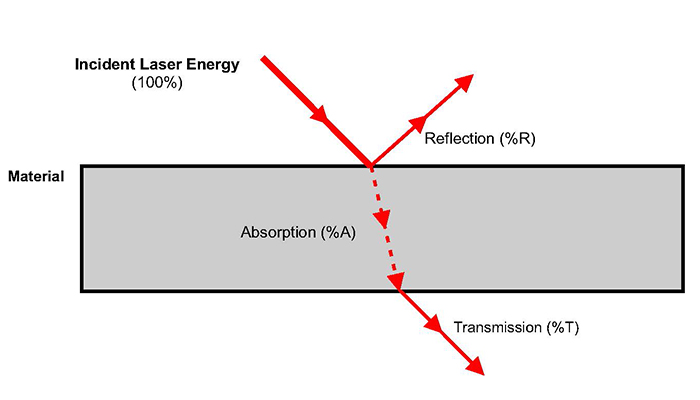

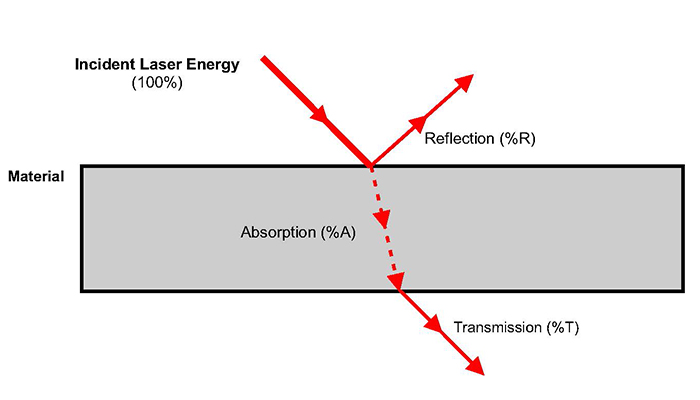

The high level of configuration flexibility allows users to precisely match the laser wavelength(s) and power to a material’s composition and properties—especially its absorption characteristics. When laser energy at a specific wavelength interacts with a material, its energy may be reflected, absorbed, or transmitted to varying degrees at the surface, within the structure, or at the exit point.

In most applications, high absorption within the material is desired for optimal results. Efficient absorption improves laser energy delivery, which can reduce heat-affected zones, minimize discoloration or deformation, enhance edge quality and visual appearance, and increase throughput—ultimately improving overall processing quality.

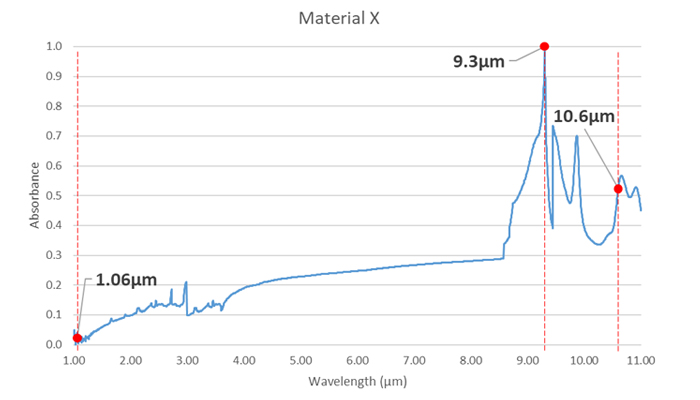

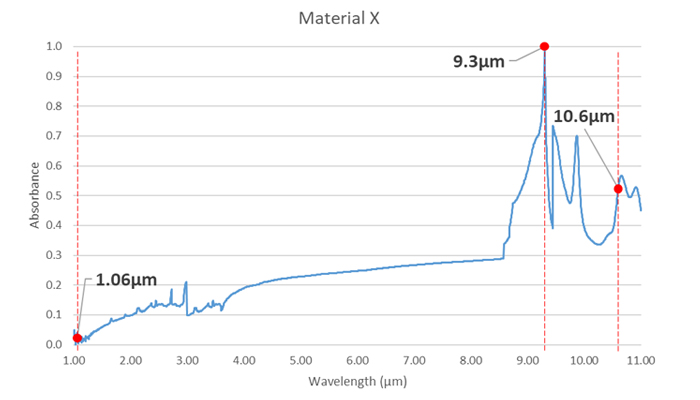

FTIR spectroscopy: Graph indicating high absorption of the 9.3 μm wavelength for an example homogeneous material X

Homogeneous Materials and Wavelengths

For homogeneous materials with uniform composition and consistent absorption properties—such as metals and plastics like polyimide, polycarbonate, and polyethylene—a single wavelength is often sufficient. Because ULS solutions support multiple wavelengths, materials compatible with 10.6, 9.3, and 1.06 μm wavelengths can all be processed on the same system with ease.

FTIR spectroscopy: Graph indicating high absorption of the 9.3 μm wavelength for an example homogeneous material X

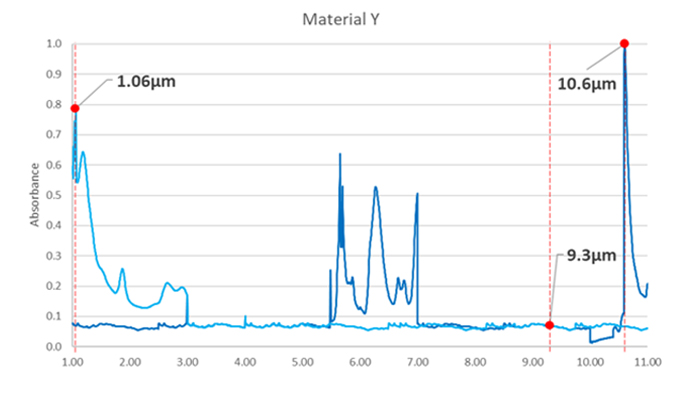

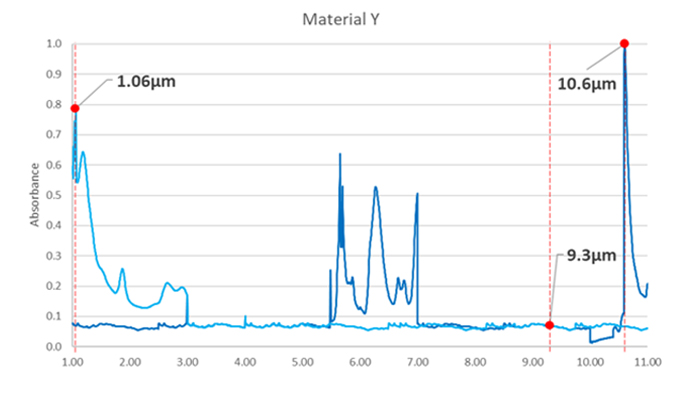

FTIR spectroscopy: Graph indicating high absorption of the 10.6 μm and 1.06 μm wavelengths for an example heterogenous material Y.

Heterogeneous Materials and Wavelengths

Heterogeneous materials such as composites are more complex due to their varied constituents, each with distinct properties and absorption behaviors. A wavelength effective for one component may be ineffective—or even damaging—for another. Using a single wavelength in such cases can result in uneven cutting, delamination, thermal damage, or the inability to process the material at all.

FTIR spectroscopy: Graph indicating high absorption of the 10.6 μm and 1.06 μm wavelengths for an example heterogenous material Y.

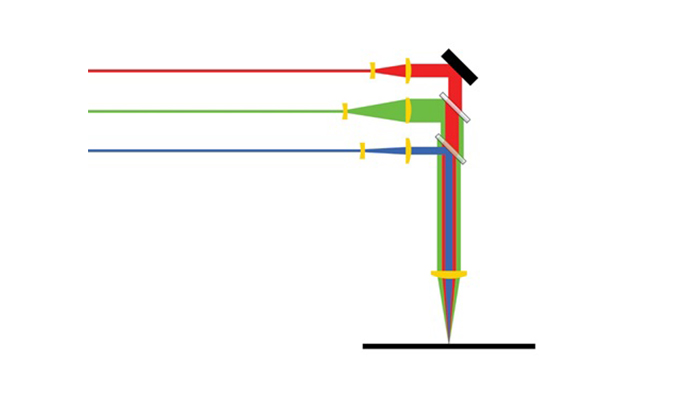

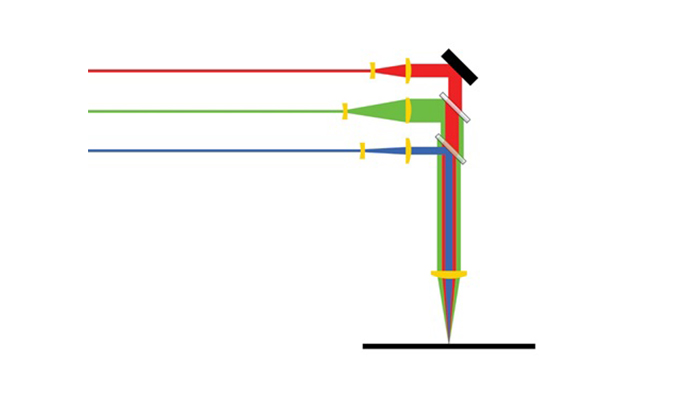

Illustration of MultiWave Hybrid Technology: Multiple laser wavelengths are combined into a single coaxial hybrid beam, all focused at the same focal plane.

MultiWave Hybrid™ Technology for Advanced Materials

In many cases, processing complex heterogeneous materials require multiple wavelengths. MultiWave Hybrid™ (MWH) Technology enables the simultaneous use of laser energy from different wavelengths through a unified, coaxial beam. Focused at a single plane, each wavelength's parameters—such as average power, duty cycle, pulse duration, pulses per inch, and beam positioning speed—can be independently controlled. This allows for precise energy distribution and beam shaping.

Additionally, MWH technology supports sequential wavelength use, where one wavelength preconditions the material to enable more efficient modification or removal by another.

Illustration of MultiWave Hybrid Technology: Multiple laser wavelengths are combined into a single coaxial hybrid beam, all focused at the same focal plane.

Processing Optimization Versatility

A variety of modules and technologies can be configured with ULS laser systems to further optimize and enhance laser processing for specific applications. These modules improve precision, productivity, material compatibility, and operational efficiency.

Key Modules and Technologies

- Controllable Laser Power Density - Allows users to easily choose the power density and focal depth best suited to their application.

- Gas Assist - Directs compressed air or inert gas through specialized nozzles to clear debris, cool the surface, reduce charring, improve edge quality, and protect optics during processing.

- Material Handling - Includes modules that support placement, accurate positioning, and movement of materials to improve repeatability and consistency.

- Automation Interface - Integrates with external systems (e.g., conveyors, robotics) to automate workflows, reduce manual intervention, and increase production throughput.

- Air Filtration and Handling - Removes fumes, byproducts, and particulates to protect system components and maintain a clean work environment.

- Camera Registration - Uses a camera to detect registration marks or virtually any feature as a point of registration and align laser operations accordingly. Enhances accuracy, repeatability, and productivity.

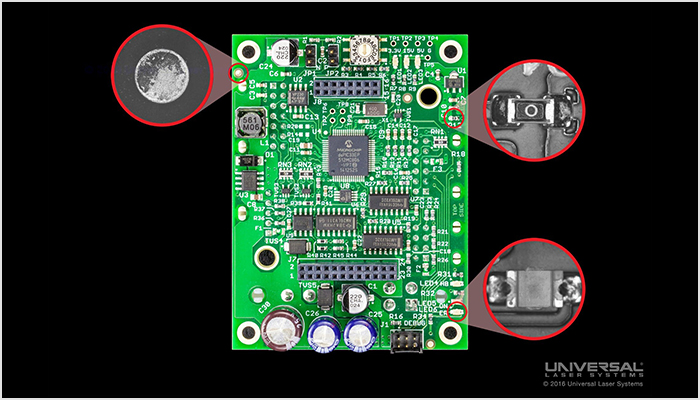

Camera Registration: Examples of different components on a circuit board used as registration points

- Class 4 Conversion Module - Converts a Class 1 laser system into a Class 4 system compliant with CDRH and international safety standards. Enables processing of oversized or irregularly shaped materials.

- Fire Suppression Assistance - Provides pressurized fire suppressant that can be automatically deployed on the material being processed if high temperatures are detected.