Engage with us if you:

- Are working with a material that is difficult to process—whether using laser technology or other methods

- Want to improve results with materials you currently process using laser technology

- Aim to expand your existing laser processing capabilities to handle a broader range of materials

- Are interested in introducing laser processing capabilities into your organization

ULS laser systems are designed to meet the most complex applications and demanding requirements in high-tech industries such as aerospace, electronics, automotive, medical devices, and more.

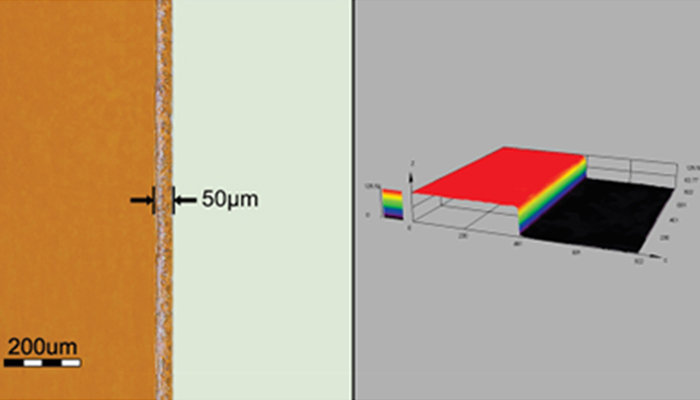

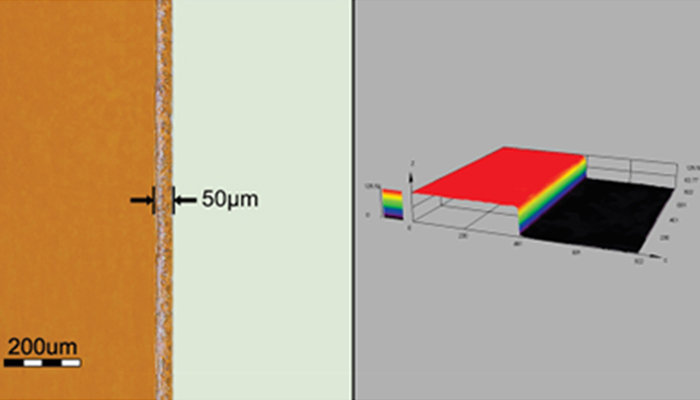

Microscopic image of kerf width and 3D analysis of heat affected zone for a material.

Material Application Testing

We employ a comprehensive, methodical, and scientific approach to assess the effectiveness and compatibility of laser technology for modifying one or more materials for your specific application(s).

Through a guided discovery process, we help you evaluate a range of factors to uncover both defined and unrecognized needs related to your business objectives and technical requirements.

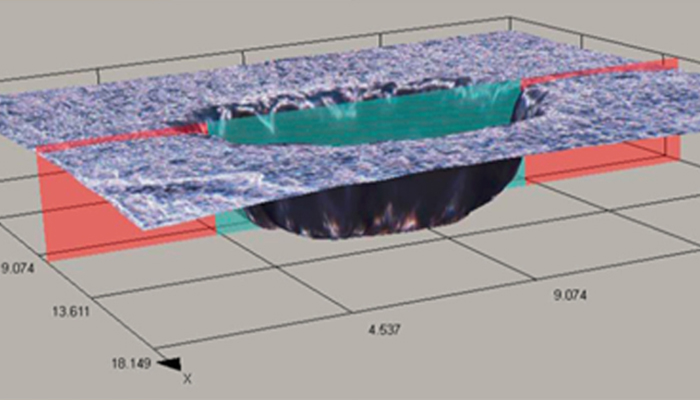

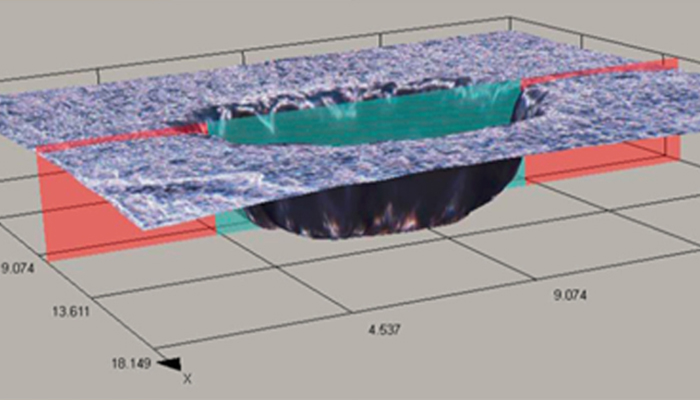

3D imaging of a depth engraving for a material.

Based on this information, we perform testing tailored to your goals. For new materials, we first characterize the material, then develop laser processing parameters and methods. Each test is conducted under controlled conditions using a structured design of experiments approach and is engineered to deliver optimal results for the materials under evaluation—ensuring that our laser technology produces precise, repeatable, and high-quality outcomes.

For known materials, we leverage our Intelligent Materials Database and optimize pre-defined settings to meet your specific requirements.

Following testing, we use state-of-the-art analytical equipment to analyze and verify the results, then provide finished samples for your internal review. We work closely with your team to determine appropriate next steps, which may include further optimization, solution configuration, or a technical demonstration—either virtually or at ULS headquarters.

Microscopic image of kerf width and 3D analysis of heat affected zone for a material.

3D imaging of a depth engraving for a material.